1.0 Introduction

Impulse sensing lines are the lines containing process fluid which run between the sensing instruments and process tapping points, and are usually made of tubing/piping, valves and tube fittings.

1.1 Difference between a pipe and a tube

The fundamental difference between pipe and tube is the dimensional standard to which each is manufactured.

A tube is a hollow product of round or any other cross section having a continuous periphery. Round tube size may be specified with respect to any two, but not all three, of the following: Outside diameter, inside diameter, wall thickness; type K, L and M copper tube (See section 6 for details) may also be specified by nominal size and type only. Dimensions and permissible variations (tolerances) are specified in the appropriate ASTM or ASME standard specifications.

Generally tubing is specified by giving O.D. and wall thickness whereas pipes are specified by giving nominal diameter & wall thickness (NB and Schedule). A pipe is a tube with a round cross section conforming to the dimensional requirements for nominal pipe size as tabulated in ANSI B36.10, Table 2 and 4, and ANSI B36.19, Table 1. For special pipe having a diameter not listed in these tables, and also for round tube, the nominal diameter corresponds with the outside diameter.

Standard fluid line systems, whether for simple household use or for the more exacting requirements of industry, were for many years constructed from threaded pipe of assorted materials and were assembled with various standard pipe fitting shapes, unions and nipples. Such systems under high pressures were plagued with leakage problems besides being cumbersome, inefficient and costly to assemble and maintain. Therefore, the use of pipe in these systems has largely been replaced by tubing because of the many advantages it offers.

Old Method – Each connection is threaded ‐ requires numerous fittings – system not flexible or easy to install and service connections not smooth inside ‐ pockets obstruct flow.

Modern Method ‐ Bendable tubing needs fewer fittings ‐ no threading required ‐ system light and compact ‐ easy to install and service ‐ no internal pockets or obstructions to free flow.

1.2 Major Advantages of Tubing over Piping Systems

1. Bending Quality ‐ Tubing has strong but relatively thinner walls; is easy to bend. Tube fabrication is simple.

2. Greater Strength ‐ Tubing is stronger as no threads are required for connection. No weakened sections from reduction of wall thickness by threading.

3. Less Turbulence ‐ Smooth bends result in streamlined flow passage and less pressure drop.

4. Economy of Space and Weight ‐ With its better bending qualities and a smaller outside diameter, tubing saves space and permits working in close quarters. Tube fittings are smaller and also weigh less.

5. Flexibility ‐ Tubing is less rigid, has less tendency to transmit vibration from one connection to another.

6. Fewer Fittings ‐ Tubing bends substitute for elbows. Fewer fittings mean fewer joints, fewer leak paths.

7. Tighter Joints ‐ Quality tube fittings, correctly assembled, give better assurance of leak‐free systems.

8. Better Appearance ‐ Tubing permits smoother contours with fewer fittings for a professional look to tubing systems.

9. Cleaner Fabrication ‐ No sealing compounds on tube connections. Again no threading; minimum chance of scale, metal chips, foreign particles in system.

10. Easier Assembly and Dis assembly ‐ Every tube connection serves as a union. Tube connections can be reassembled repeatedly with easy wrench action.

11. Less Maintenance ‐ Advantages of tubing and tube fittings add up to dependable, trouble‐free installations.

1.3 Types of tubes

Tubes can be categorized in different ways.

1. Categorization based on tube dimensional specifications: Tubes can be classified as

a. Metric tubes, where dimensions are specified in mm units e.g. 10mm, 20 mm etc.

b. Fractional tubes, where dimensions are specified in inch units e.g. ½”, ¾”, 1” etc.

2. Categorization based on material of tubes e.g. carbon steel tubes, PVC Tubes, Copper tubes, SS tubes, Inconel tubes, etc.

3. Categorization based on method of tube drawing i.e. welded and drawn, seamless etc.

1.4 Guidelines for selection of instrumentation tubes

Proper Tubing Selection

1. Always Match Materials – S.S. Tubing should be used only with S.S. Fittings. The only exception to this rule is copper tubing with brass fittings. Mixing materials can cause galvanic corrosion.

Galvanic Corrosion (Electrochemical)

All metals have a specific relative electrical potential. When dissimilar metals come in contact in the presence of moisture (electrolyte), a low intensity electric current flows from the metal having the higher potential to the metal having the lower potential. The result of this galvanic action is the corrosion of the metal with the higher potential (more anodic). (See Galvanic Series Chart)

2. Select proper tubing hardness – Remember instrumentation tube Fittings are designed to work within specific hardness ranges. RB 90 maximum for S.S., RB 80 recommended. For proper swaging the hardness of the tube should be less than the hardness of the fitting.

3. Select proper tubing wall thickness – Proper wall thickness is necessary to accommodate accepted safety factors relative to desired working pressures.

4. Tubing surface finish – Always select tubing free of visible draw marks or surface scratches. If possible, cut off any undesirable sections. These “deep” scratches can cause leaks when attempting to seal low‐density gases such as argon, nitrogen, or helium. Proper surface finish ensures leak‐proof compression joint with fitting.

1.5 Different sizes of tubes

Following tube sizes have been used in NPCIL NPPs

1.6 Criteria for selecting the size of a tube

The selection criteria for sizing the tube are as follows:

• The O.D. of the tubes/impulse tubes should be the same and not smaller than 6 mm even with clean liquids and non corrosive piping, owing to the chance of blockage after long service.

• If condensation is likely to occur or if gas bubbles are likely to be liberated, the O.D. should not be smaller than 10 mm.

• When long runs cannot be avoided, the internal diameter of impulse tubing/piping may be selected as per the following table‐1‐1:

As very long runs of impulse tubing/piping are not expected in our systems and also process fluid is expected to be clean, 10 mm OD tubing having I.D. of 7.6 mm has been found to be adequate, for pressure/ ΔP measurement except for some cases for level measurement in tanks/vessels using ΔP principle.

• Based on hold up, installation and material cost, radiation streaming considerations, higher size (>10 mm OD) tubing is not recommended for pressure/ΔP measurement in primary/nuclear system in general.

1.7 Selection and Design criteria

Following requirements should be met for impulse tubing for sensing the pressure/differential pressure signal for all types of process systems including for safety and safety related systems.

The most important consideration in the selection of suitable tubing for any application is the compatibility of the tubing material with the media to be contained. Table 1‐2 lists common materials and their associated general application. Table 1‐2 also lists the maximum and minimum operating temperature for the various tubing materials. Properly designed tubing/piping based on service conditions, should only be used for sensing lines.

The practice of mixing materials should be strongly discouraged. The only exception is brass fittings with copper tubing. Dissimilar materials in contact may be susceptible to galvanic corrosion. Further, different materials have different levels of hardness, and can adversely affect the fittings ability to seal on the tubing.

The use of a particular type of tube for a specific usage depends on the application and the process condition. The following table briefly describes the application guidelines for a specific tube material.

1. For operating temperatures above 800 °F (425 °C), consideration should be given to media. 300 Series Stainless Steels are susceptible to carbide precipitation which may lead to intergranular corrosion at elevated temperatures.

2. All temperature ratings based on temperatures as per ASME/ANSI B313 Chemical Plant and Petroleum Refinery Piping Code, 1999 Edition.

Gas Service

Special care must be taken when selecting tubing for gas service. In order to achieve a gastight seal, ferrules in instrument fittings must seal any surface imperfections. This is accomplished by the ferrules penetrating the surface of the tubing. Penetration can only be achieved if the tubing provides radial resistance and if the tubing material is softer than the ferrules.

Thick walled tubing helps to provide resistance. Tables‐1‐3 to 1‐10 below indicate the minimum acceptable wall thickness for various materials in gas service. The ratings in white indicate combinations of diameter and wall thickness which are suitable for gas service. Acceptable tubing hardness for general application is listed in Table 1‐12.

These values are the maximum allowed by the ASTM. For gas service, better results can be obtained by using tubing well below this maximum hardness. For example, a desirable hardness of 80 RB is suitable for stainless steel. The maximum allowed by ASTM is 90 RB.

System Pressure

The system operating pressure is another important factor in determining the type, and more importantly, the size of tubing to be used. In general, high pressure installations require strong materials such as steel or stainless steel. Heavy walled softer tubing such as copper may be used if chemical compatibility exists with the media. However, the higher strength of steel or stainless steel permits the use of thinner tubes without reducing the ultimate rating of the system. In any event, tube fitting assemblies should never be pressurized beyond the recommended working pressure.

The following tables (1‐3 to 1‐10) list by material the maximum suggested working pressure (in psi) of various tubing sizes. Acceptable tubing diameters and wall thicknesses are those for which a rating is listed. Combinations which do not have a pressure rating are not recommended for use with instrument fittings.

Note:

• All working pressures have been calculated using the maximum allowable stress levels in accordance with ASME/ANSI B31.3, Chemical Plant and Petroleum Refinery Piping or ASME/ANSI B31.1 Power Piping.

• All calculations are based on maximum outside diameter and minimum wall thickness.

• All working pressures are at ambient (72°F) temperature.

• Ratings in gray are not suitable for gas services.

Systems Temperature

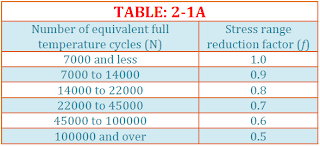

Operating temperature is another factor in determining the proper tubing material. Copper and aluminum tubing are suitable for low temperature media. Stainless steel and carbon steel tubing are suitable for higher temperature media. Special alloys such as Alloy 600 are recommended for extremely high temperature (see Table 1‐2). Table 1‐11 lists de‐rating factors which should be applied to the working pressures listed in Table 1‐3 to 1‐10 for elevated temperature (see Table 1‐2). Simply locate the correct factor in Table 1‐11 and multiply this by the appropriate value in Tables 1‐3 to 1‐10 for the elevated temperature working pressure.

EXAMPLE: 1/2 inch x .049 wall seamless stainless steel tubing has a working pressure of 3700 psi @ room temperature. If the system were to operate @ 800°F (425°C), a factor of 80% (or .80) would apply (see Table 111 above) and the “at temperature” system pressure would be 3700 psi x .80 = 2960 psi

Impulse sensing lines are the lines containing process fluid which run between the sensing instruments and process tapping points, and are usually made of tubing/piping, valves and tube fittings.

1.1 Difference between a pipe and a tube

The fundamental difference between pipe and tube is the dimensional standard to which each is manufactured.

A tube is a hollow product of round or any other cross section having a continuous periphery. Round tube size may be specified with respect to any two, but not all three, of the following: Outside diameter, inside diameter, wall thickness; type K, L and M copper tube (See section 6 for details) may also be specified by nominal size and type only. Dimensions and permissible variations (tolerances) are specified in the appropriate ASTM or ASME standard specifications.

Generally tubing is specified by giving O.D. and wall thickness whereas pipes are specified by giving nominal diameter & wall thickness (NB and Schedule). A pipe is a tube with a round cross section conforming to the dimensional requirements for nominal pipe size as tabulated in ANSI B36.10, Table 2 and 4, and ANSI B36.19, Table 1. For special pipe having a diameter not listed in these tables, and also for round tube, the nominal diameter corresponds with the outside diameter.

Pipe versus Tubes

Standard fluid line systems, whether for simple household use or for the more exacting requirements of industry, were for many years constructed from threaded pipe of assorted materials and were assembled with various standard pipe fitting shapes, unions and nipples. Such systems under high pressures were plagued with leakage problems besides being cumbersome, inefficient and costly to assemble and maintain. Therefore, the use of pipe in these systems has largely been replaced by tubing because of the many advantages it offers.

Old Method – Each connection is threaded ‐ requires numerous fittings – system not flexible or easy to install and service connections not smooth inside ‐ pockets obstruct flow.

Modern Method ‐ Bendable tubing needs fewer fittings ‐ no threading required ‐ system light and compact ‐ easy to install and service ‐ no internal pockets or obstructions to free flow.

1.2 Major Advantages of Tubing over Piping Systems

1. Bending Quality ‐ Tubing has strong but relatively thinner walls; is easy to bend. Tube fabrication is simple.

2. Greater Strength ‐ Tubing is stronger as no threads are required for connection. No weakened sections from reduction of wall thickness by threading.

Figure 1-2: With no threading necessary, tubing does not require extra wall thickness

3. Less Turbulence ‐ Smooth bends result in streamlined flow passage and less pressure drop.

4. Economy of Space and Weight ‐ With its better bending qualities and a smaller outside diameter, tubing saves space and permits working in close quarters. Tube fittings are smaller and also weigh less.

5. Flexibility ‐ Tubing is less rigid, has less tendency to transmit vibration from one connection to another.

6. Fewer Fittings ‐ Tubing bends substitute for elbows. Fewer fittings mean fewer joints, fewer leak paths.

7. Tighter Joints ‐ Quality tube fittings, correctly assembled, give better assurance of leak‐free systems.

8. Better Appearance ‐ Tubing permits smoother contours with fewer fittings for a professional look to tubing systems.

9. Cleaner Fabrication ‐ No sealing compounds on tube connections. Again no threading; minimum chance of scale, metal chips, foreign particles in system.

10. Easier Assembly and Dis assembly ‐ Every tube connection serves as a union. Tube connections can be reassembled repeatedly with easy wrench action.

11. Less Maintenance ‐ Advantages of tubing and tube fittings add up to dependable, trouble‐free installations.

1.3 Types of tubes

Tubes can be categorized in different ways.

1. Categorization based on tube dimensional specifications: Tubes can be classified as

a. Metric tubes, where dimensions are specified in mm units e.g. 10mm, 20 mm etc.

b. Fractional tubes, where dimensions are specified in inch units e.g. ½”, ¾”, 1” etc.

2. Categorization based on material of tubes e.g. carbon steel tubes, PVC Tubes, Copper tubes, SS tubes, Inconel tubes, etc.

3. Categorization based on method of tube drawing i.e. welded and drawn, seamless etc.

1.4 Guidelines for selection of instrumentation tubes

Proper Tubing Selection

1. Always Match Materials – S.S. Tubing should be used only with S.S. Fittings. The only exception to this rule is copper tubing with brass fittings. Mixing materials can cause galvanic corrosion.

Galvanic Corrosion (Electrochemical)

All metals have a specific relative electrical potential. When dissimilar metals come in contact in the presence of moisture (electrolyte), a low intensity electric current flows from the metal having the higher potential to the metal having the lower potential. The result of this galvanic action is the corrosion of the metal with the higher potential (more anodic). (See Galvanic Series Chart)

Figure1-3: Galvanic Series chart

2. Select proper tubing hardness – Remember instrumentation tube Fittings are designed to work within specific hardness ranges. RB 90 maximum for S.S., RB 80 recommended. For proper swaging the hardness of the tube should be less than the hardness of the fitting.

3. Select proper tubing wall thickness – Proper wall thickness is necessary to accommodate accepted safety factors relative to desired working pressures.

4. Tubing surface finish – Always select tubing free of visible draw marks or surface scratches. If possible, cut off any undesirable sections. These “deep” scratches can cause leaks when attempting to seal low‐density gases such as argon, nitrogen, or helium. Proper surface finish ensures leak‐proof compression joint with fitting.

1.5 Different sizes of tubes

Following tube sizes have been used in NPCIL NPPs

- SS Tubes (metric): 6 mm, 10mm, 12mm, 20mm and 25mm.

- SS tube (Fractional): ¼”, 3/8”, ½”, ¾” and 1”.

- Copper tubes (metric): 6mm, 10mm, 12mm, 20mm and 25mm.

- Copper tubes (Fractional): ¼”, 3/8”, ½”, ¾” and 1”.

1.6 Criteria for selecting the size of a tube

The selection criteria for sizing the tube are as follows:

• The O.D. of the tubes/impulse tubes should be the same and not smaller than 6 mm even with clean liquids and non corrosive piping, owing to the chance of blockage after long service.

• If condensation is likely to occur or if gas bubbles are likely to be liberated, the O.D. should not be smaller than 10 mm.

• When long runs cannot be avoided, the internal diameter of impulse tubing/piping may be selected as per the following table‐1‐1:

TABLE – 1-1

As very long runs of impulse tubing/piping are not expected in our systems and also process fluid is expected to be clean, 10 mm OD tubing having I.D. of 7.6 mm has been found to be adequate, for pressure/ ΔP measurement except for some cases for level measurement in tanks/vessels using ΔP principle.

• Based on hold up, installation and material cost, radiation streaming considerations, higher size (>10 mm OD) tubing is not recommended for pressure/ΔP measurement in primary/nuclear system in general.

1.7 Selection and Design criteria

Following requirements should be met for impulse tubing for sensing the pressure/differential pressure signal for all types of process systems including for safety and safety related systems.

The most important consideration in the selection of suitable tubing for any application is the compatibility of the tubing material with the media to be contained. Table 1‐2 lists common materials and their associated general application. Table 1‐2 also lists the maximum and minimum operating temperature for the various tubing materials. Properly designed tubing/piping based on service conditions, should only be used for sensing lines.

The practice of mixing materials should be strongly discouraged. The only exception is brass fittings with copper tubing. Dissimilar materials in contact may be susceptible to galvanic corrosion. Further, different materials have different levels of hardness, and can adversely affect the fittings ability to seal on the tubing.

The use of a particular type of tube for a specific usage depends on the application and the process condition. The following table briefly describes the application guidelines for a specific tube material.

Table1-2

1. For operating temperatures above 800 °F (425 °C), consideration should be given to media. 300 Series Stainless Steels are susceptible to carbide precipitation which may lead to intergranular corrosion at elevated temperatures.

2. All temperature ratings based on temperatures as per ASME/ANSI B313 Chemical Plant and Petroleum Refinery Piping Code, 1999 Edition.

Gas Service

Special care must be taken when selecting tubing for gas service. In order to achieve a gastight seal, ferrules in instrument fittings must seal any surface imperfections. This is accomplished by the ferrules penetrating the surface of the tubing. Penetration can only be achieved if the tubing provides radial resistance and if the tubing material is softer than the ferrules.

Thick walled tubing helps to provide resistance. Tables‐1‐3 to 1‐10 below indicate the minimum acceptable wall thickness for various materials in gas service. The ratings in white indicate combinations of diameter and wall thickness which are suitable for gas service. Acceptable tubing hardness for general application is listed in Table 1‐12.

These values are the maximum allowed by the ASTM. For gas service, better results can be obtained by using tubing well below this maximum hardness. For example, a desirable hardness of 80 RB is suitable for stainless steel. The maximum allowed by ASTM is 90 RB.

System Pressure

The system operating pressure is another important factor in determining the type, and more importantly, the size of tubing to be used. In general, high pressure installations require strong materials such as steel or stainless steel. Heavy walled softer tubing such as copper may be used if chemical compatibility exists with the media. However, the higher strength of steel or stainless steel permits the use of thinner tubes without reducing the ultimate rating of the system. In any event, tube fitting assemblies should never be pressurized beyond the recommended working pressure.

The following tables (1‐3 to 1‐10) list by material the maximum suggested working pressure (in psi) of various tubing sizes. Acceptable tubing diameters and wall thicknesses are those for which a rating is listed. Combinations which do not have a pressure rating are not recommended for use with instrument fittings.

Table 1-3: Fractional 316 or 304 STAINLESS STEEL (Seamless)

Table 1-4: Fractional 316 or 304 STAINLESS STEEL (Welded & Drawn)

Table 1-5: Seamless Stainless Steel metric tubing

Table 1-6: Fractional Carbon Steel (Seamless)

Table 1-7: Carbon Steel Metric tubing

Table 1-8: Aluminium (Seamless)

Table1-9: Copper (Seamless)

Table 1-10: MONEL 400 (Seamless)

Note:

• All working pressures have been calculated using the maximum allowable stress levels in accordance with ASME/ANSI B31.3, Chemical Plant and Petroleum Refinery Piping or ASME/ANSI B31.1 Power Piping.

• All calculations are based on maximum outside diameter and minimum wall thickness.

• All working pressures are at ambient (72°F) temperature.

• Ratings in gray are not suitable for gas services.

Systems Temperature

Operating temperature is another factor in determining the proper tubing material. Copper and aluminum tubing are suitable for low temperature media. Stainless steel and carbon steel tubing are suitable for higher temperature media. Special alloys such as Alloy 600 are recommended for extremely high temperature (see Table 1‐2). Table 1‐11 lists de‐rating factors which should be applied to the working pressures listed in Table 1‐3 to 1‐10 for elevated temperature (see Table 1‐2). Simply locate the correct factor in Table 1‐11 and multiply this by the appropriate value in Tables 1‐3 to 1‐10 for the elevated temperature working pressure.

EXAMPLE: 1/2 inch x .049 wall seamless stainless steel tubing has a working pressure of 3700 psi @ room temperature. If the system were to operate @ 800°F (425°C), a factor of 80% (or .80) would apply (see Table 111 above) and the “at temperature” system pressure would be 3700 psi x .80 = 2960 psi