In ASME

Section III‐Division‐I sub‐section NB (Class I components), the design criterion/design

requirements for instrument tubing has not been covered separately. Thus design

guidelines given for small size of piping is being followed for Class I

instrument tubing also. Also as the outside diameter of instrument tubing is

being limited to 1” (25 mm); so any design concession permitted for lower size

piping (<1”) will also be applicable to instrument tubing.

As per NB

3630 (Piping design and analysis criteria) the piping of 1” NB or less, which

have been classified as class I in design specification, may be designed and

analyzed as per subsection NC.

Thus for

instrument tubing, the material & testing requirements shall be as per

subsection NB whereas the design and analysis will be as per subsection NC.

a. Pressure

retaining material should confirm to the requirements of one of the specifications

for material given in NB‐2121.

b. Impact testing

for austenitic stainless steel is not required. Also impact testing is not required

for a pipe/tube with a nominal pipe size less than 6”, irrespective of wall thickness.

c. Seamless

pipes, tubes and fittings need not be examined by the rule of NB‐2510(examination

of pressure retaining material).

d. Wrought

seamless and welded (without filler metal) pipes and tubes shall be examined

and may be repaired in accordance with the requirements of class‐I seamless and

welded (without filler metal) piping and tubing of SA‐655 (specification for

special requirements for pipe and tubing for nuclear and other applications).

i. MAXIMUM

ALLOWABLE STRESS

For

design/calculating minimum wall thickness of instrument tubing/piping, the maximum

allowable stress for the material at design temperature shall be used as given

in ANSI/ASME B36.19.

ii. PRESSURE

AND TEMPERATURE RATINGS

The pressure

ratings at the corresponding temperature given in ANSI/ASME B36.19 shall not be

exceeded and piping/tubing product shall not be used at temperature in excess

of those given in ANSI/ASME B36.19 for all the materials of which the tubing is

made.

iii.

ALLOWANCES

Increased

wall thickness of tubing shall be taken for providing allowances for corrosion

or erosion, mechanical strength & bending etc.

iv. DYNAMIC

EFFECTS

Impact

forces caused by either external or internal loads shall be considered in the piping/tubing

design. Also the effect of earthquake and non‐seismic vibration shall be

considered in the tubing design.

a) Minimum

Wall Thickness of straight tube/pipe:

The minimum

wall thickness of straight tube/pipe shall not be less than that determined by

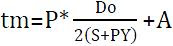

eq. (I) as follows:

tm = minimum

required wall thickness, mm

P = Internal

design pressure, kPag

DO = Outside

diameter of tube/pipe, mm

S = Maximum

allowable stress in the material due to internal pressure and joint efficiency

at design temperature, kPa

A =

Additional thickness, to provide for material removed in threading, corrosion and

erosion allowances and allowance for structural strength needed during erection.

value of ‘Y’

for ferritic and austenitic steels designed for temperature of 480 oC and below

should be taken as per eq. (2) below

d = Inside

diameter of tube/pipe.

b) Wherever

bending of tubing/piping is likely to be involved in installations, the minimum

wall thickness after bending shall not be less than the minimum wall thickness

calculated as per eq. (1) for straight tube/pipe. To meet this requirement,

actual wall thickness of tubing/piping is to be increased as per following

Table –2‐1 (This is based on NC 3000):

c) Also, unless otherwise justified by the design calculation the ovality of tubing/piping after bending should not exceed 8% as determined by following eq. (3).

Do = Nominal

outside diameter of tube/pipe

Dmax = the

maximum outside diameter after bending or forming

Dmin = the

minimum outside diameter after bending or forming

Analysis

requirements for tubing/piping systems as per NC‐3650 are given below. “The

design of complete piping system shall be analyzed between anchors for the effects

of thermal expansion, weight and other sustained and oCcasional loads.” The

detail requirements/analysis criteria are given in following sub‐sections.

a.

CONSIDERATION OF DESIGN CONDITIONS (STRESS DUE TO SUSTAINED LOADS)(Refer NC

3652)

The effects

of pressure, weight and other sustained mechanical loads must meet the requirements

of following eq. (4).

Ssl = Stress

due to sustained loads, kPa

P = Internal

design pressure, mm

Do = Outside

diameter of tube/pipe, mm

B1, B2 =

Primary stress indices for the pipe/tube (As per Figure below) NC 3673.2 (b)1

MA =

Resultant moment loading on cross section due to weight and other sustained loads, kN‐m. NC 3653.3

Z =

Sectional modulus of pipe/tube, mm3

Sh = Basic

material allowable stress at design temperature consistent with loading under

consideration.

tn = Nominal

wall thickness, mm

b.

CONSIDERATION OF LEVEL A AND B SERVICE LIMITS (REF. NC3653)

i. STRESS

DUE TO SUSTAINED PLUS OCCASIONAL LOADS

The effect

of pressure, weight, other sustained loads and oCcasional loads including earthquake,

for which level B service limits are designated, must meat the requirements of following

eq. (5).

Where

Mb =

resultant moment loading on cross section due to non reversing dynamic loads

e.g. oCcasional loads such as thrust from relief and safety valves loads from

pressure and flow transients and earthquake.

Sy =

material yield strength at temperature consistent with the loading under consideration,

kPa.

Sol = stress

due to oCcasional loads, kPa.

Pmax = Peak

pressure, kPa

ii.

SUSTAINED PLUS THERMAL EXPANSION STRESSES

The effects

of pressure, weight, other sustained loads and thermal expansion for which

level A and B service limits are designated, shall meet the requirements of

following eq. (6).

Where

Ste =

Sustained plus thermal expansion stresses.

MC = range

of resultant moments due to thermal expansion

SA =

Allowable stress range for expansion stresses.

i = Stress

intensification factor (refer NC‐3673.2)

= ratio of bending moment producing fatigue in a given number of cycles in a straight pipe/tube with girth butt weld to that producing failure in the same number of cycles in the fitting or joint under consideration.

Other terms are same as of eq. (4)

Allowable stress

range for expansion stresses (SA) can be calculated using following equation

SA = ƒ(1.25

SC + 0.25 Sh) ……. (7)

SC = Basic

material allowable stress at minimum (cold) temperature.

Sh = Basic

material allowable stress at maximum (hot) temperature.

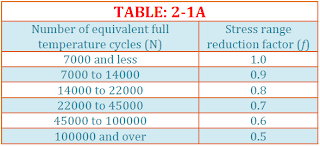

f = stress

range reduction factor for cyclic conditions for total number N of full

temperature

cycles over total number of years during which system is

expected to

be in service from table‐2‐1A below NC 3611.2 (e)‐1

Stress

intensification factor ‘i’ can be calculated using following equation (8)

Where

C2 and K2

are stress indices for class‐1 piping products or joints from NB 3681 (a)‐1.

For straight pipe/tube the value of C2 and k2 are 1.

For curved

pipe/tube or welded elbows ‘I’ can be computed as per equation (9) below (refer

NB 3681)

tn = nominal wall thickness of tube/pipe

R = bend

radius

r = mean

radius of tube/pipe

iii.

CONSIDERATION OF LEVEL C SERVICE LIMITS

In section

II in calculating the resultant moment MB, moment due to SEE conditions is proposed

to be used which is more conservative, thus separate analysis for level C

service limits is not required.

iv. TESTING

REQUIREMENTS AS PER SUBSECTION – NB

Requirements

of material testing as per subsection NB is briefly mentioned above. In addition

to examination/testing requirements as per SA‐655, tubing should be hydrostatically

tested at not less than 1.25 times the design pressure with minimum holding time

of 10 min.

The maximum

design pressure and temperature are taken as 195 kg/cm2 and 310oC respectively.

Though the above pressure and temperature may not exist simultaneously in any

system, still to be on conservative side, all the sizes of tubing will be

designed for above ratings.

Using eq.

(1) in the analysis criteria above, the minimum wall thickness of straight

tubing can be calculated.

Thus

following equation can be used

We can make

following assumptions

• There will

be no threading on the tubes

• Corrosion,

erosion is negligible (hence allowance for corrosion and erosion may be

neglected)

• Bend

radius is not less than 3Do. The actual wall thickness is to be increased as per

Table‐2‐1 above.

Following

data may be used

P = design

pressure (= 195 kg/cm2)

S = maximum

allowable stress of S.S. 304L material at 310oC temp. (= 986 kg/cm2)

Y = 0.4

By putting

the above variables, the minimum wall thickness for different sizes (Do) of straight

tubing is tabulated in following Table‐2‐2.

Note: It can

be seen from Tables – 22 & 23 that specified wall thickness of all sizes of

tubing as per PBM17 is more than required wall thickness as per ASME Section

III except for 16 mm size. As maximum pressure and temperature may not be

simultaneous so 1.8 mm wall thickness instead for 1.83 mm of 16 mm size will be

adequate from pressure rating considerations.

“For

example, the maximum pressure & temperature in PHT system will be 125

kg/cm2 and 310oC respectively. For this application, the required minimum wall

thickness for 16mm OD tube, including the bending allowance, should be 1.3 mm,

which is less than specified wall thickness of 1.8 mm. Similarly, in some

applications like F/M supply circuit, the maximum pressure and temperature may

be 195 kg/cm2 and 40oC respectively. For this service also, the minimum required

wall thickness including the bending allowance for 16mm OD tube should be

1.62mm which is less than specified wall thickness of 1.8 mm”.

When the

tubing is installed in the field, the effects of pressure, weights and other sustained

mechanical loads must meet the requirements of eq. (4) i.e.

The above

equation may be verified for different sizes of tubing having wall thickness as

given in Table‐2‐2 and other constants to be calculated/taken as below:

B1 = 0.5 (as

per NB – 3680)

Where

tn = nominal

wall thickness of tube

R = Bend

radius

r = (Do –

t)/2 = mean radius of tubing

Thus for

different sizes of tubing systems Ssl value is tabulated in Table‐2‐4

As per

requirement of ASME – Section III installed tubing system should satisfy the equation

(5) of Section 4.2.1 as given below:

Based on the seismic analysis carried out for different tubing layouts, the recommended conservative value of Mb is 200 kg mm for all sizes of tubing systems for SSE level of earthquake. Thus for different sizes of tubing systems Sol value is tabulated in Table‐2‐4. This can be seen that Sol is less than 1.8 Sh for all the sizes of tubing thus satisfying the above equation.

As per

requirement of ASME Section III installed tubing system should satisfy the following

equation

The maximum value of stress (iMc/Z) due to thermal loading (temperature variation from 25oC to 310oC) for different tubing systems comes out to be 1600 kg/cm2 provided that tubing system is supported as per recommended practices. Based on the above data and other parameters/constants, Ste has been calculated & tabulated in TABLE‐2‐3 for different sizes of tubing.

This may be

seen from the table that Ste value for different sizes of tubing is less than

the value of Sh + SA (viz. 2615 kg/cm2).

Note:

1. The

values of MA, Z, P, Sh used for calculation of STE are same as given in

Table24.

2. The value

of used is based on requirement

such that 0.75 should not be less than

1.0

3. SA = f

(1.25 Sc + 0.25 Sh) where f = 1 & Sc = 1106 (kg/cm2)

The design

of tubing/piping systems for sensing lines should take account of all the

forces and moments resulting from thermal expansion and contraction and from

the effects of expansion joints if any.

Bend radius

in instrument tubing/piping should be subject to following limitations;

i) Minimum

wall thickness at any point in the completed bends should not be less than

required minimum wall thickness for the design pressure.

ii) The

ovality of instrument tubing/piping after bending should not exceed

8% as

calculated below:

Do = Nominal

O.D. of tube/pipe

Dmin = The

min. outside diameter of tube/pipe after bending

Dmax = The

max. outside diameter after bending

The above

requirements are met if bend radius is more than 3Do.

In addition

to the general requirements of impulse connections as mentioned above, the

following requirements should also be met for impulse connections for pressure/differential

pressure measurement in safety and safety related systems. For safety and

safety-related systems the safety classification of instrument sensing lines

including the first accessible isolating valves should at least remain the same

as that of process systems, and from the valves up to instruments they should

meet at least the requirements of ANSI-B-31.1.

SS tubes

should meet the design intent of ASME Section III sub-section NB/NC.

For seismic

classification the instrument sensing lines should be of SSE Category for

safety and safety-related instrumentation systems.

A single

instrument sensing line should not be used to perform both a safety-related function

and a non safety-related function unless the following can be shown:

a. The

failure of the common sensing line would not simultaneously

1. cause an

action in a non-safety-related system that results in a plant condition

requiring protective action and

2. also

prevent proper action of a protection system channel designed to protect

against the condition.

Tubing

system should be such that the failure of non safety impulse line/tubing should

not affect the reading of safety system.

1) MATERIAL

SELECTION

a. Based on

the requirements of corrosion resistance, tensile strength, hardness and

weldability, austenitic stainless steel grade SS-304L material as per ASTM

A-213/SA655 has been selected and specified for instrument tubing. Also the

instrument SS tubing should be seamless, cold finished and

full

annealed. From welding consideration the tubing should have delta ferrite of 5

to 10%.

b. Based on

the requirements of different applications the tubing in different sizes have

been specified i.e. OD of 6mm, 10mm, 12mm, 16mm, 20mm and 25mm.

2)

NON-DESTRUCTIVE INSPECTION

All finished

tubing should be inspected by ultrasonic or eddy current methods or any

combination of these methods in accordance with the requirements of NB-2550.

3) Based on

the analysis of tubing systems carried out above for our installations the stress

values for different loading (service limits) are well within the required limits.

4) Thus, if

SS 304L instrument tubing are supplied as per specification above and installation

of tubing systems is done as per recommended practices(see section-10) then

instrument impulse tubing systems will be meeting the intent of ASME Section

III-Sub-Section NB-Class I components.

"We are online transport company in india

ReplyDeleteWe provide trucks for transportation and also giving instant price checking service.

Trucks for full load and part load we provide."

transporters in bangalore

transporters in kolkata

transporters in Hyderabad

Top 100 Transporter india

transporters in Bhiwandi

Thanks for sharing this informative post. It's very helpful. Keep it up!

ReplyDeleteMagnamike 8600

Hi..

ReplyDeleteI appreciate your Informative post and thanks for sharing.

MagnaMike 8600 – Bottle Thickness Gauge

Hi..

ReplyDeleteI appreciate your Informative post and thanks for sharing.

Wall Thickness Gauge 8600

Stainless Steel Flat bar Dealer in Ahmedabad

ReplyDeleteDiamond metal is one the best Manufacturer and dealers for stainless steel raw material And flat bar dealers in ahmedabad and Stainless steel Pipe and fittings and flange Manufacturer in Ahmedabad S S Plate Dealer in Ahmedabad Gujarat India.

This comment has been removed by the author.

ReplyDeleteYour blog provided us with valuable information to your post. Thanks a lot for sharing

ReplyDeleteStainless steel pipe

Hey guys, If you're looking for the trusted Turbine manufacturers company in India, feel free to check out Nconturbines.com who is doing best at their field. Don't miss it!

ReplyDeleteGreat effort. I liked how you went through every detail of the subject. I'd like to learn more about what you said regarding the subject. Look into Carbon Steel Flanges if at all possible.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteFound your blog interesting to read. This article is really very interesting and effective. You might like Alloy Steel Pipes & Tubes Manufacturer in India. Tirox Steel is one of the leading Alloy Steel Pipes & Tubes Manufacturers in India. Our range of Alloy Steel Pipes & Tubes include Alloy Steel Seamless Pipes & Tubes, Alloy Steel Welded Pipes & Tubes.

ReplyDeleteUseful post, You can also visit Round Bars Manufacturers in India

ReplyDeleteNice blog, by the way. Thanks for sharing this information. In the long term, I would like to see more blogs. You can also visit:Copper Earthing Electrode

ReplyDeleteYour blog is so easy to understand , just checking out some website and i got this cool content on Renown Earth.

ReplyDeleteEarth Pit Cover

fedex packers and movers in mumbai

ReplyDeletegati packers and movers in mumbai

packers and movers in mumbai

leo packers and movers in mumbai

movers and packers bill for claim mumbai

vrl packers and movers in mumbai

fedex packers and movers in bangalore

gati packers and movers in bangalore

Very helpful blog for finding new sources to further my knowledge. Aluminium Tape Bare, Copper Tape Bare

ReplyDeleteExcellent article! On our website, we will provide a link to this content, which is very fantastic. Keep writing well, please. Incoloy 800 Fasteners, Incoloy 926 Fasteners

ReplyDeleteContinue to provide excellent articles and explanations. Duplex Steel 2205 Sheets, ASTM A240 UNS S32760 Plates

ReplyDeleteGreat information on blog. very eager for next section.

ReplyDeletewe manufacture Welding Machine in Chandigarh.

Thanks for the lovely information that motivates a lot and gives proper information to information seekers, please provides few information about MS Pipe Distributors who deals in Seamless Pipe Dealers and Galvanized Pipe.

ReplyDeleteThanks for sharing nice blog about Tubing Design & Tubing System. If you want to know more information about Pipe & Tubes Follow Below Link.

ReplyDeleteClick Here :-Pipe & Tubes In Ahmedabad

Wow very good article keep it up! A salt spray chamber is used for conducting corrosion resistance tests of different products across various industries. The salt spray chamber could be quick, reproducible and well-standardised. With the help of a salt spray test chamber, manufacturers can determine the resistance of their products in corrosive environments. A vital instrument for evaluating the corrosion resistance of materials and coatings is the salt spray chamber.

ReplyDeleteThis article provides a thorough breakdown of instrument tubing design, covering material requirements, stress analysis, and pressure design. It effectively explains the technical aspects crucial for safe operation. If you're looking for reliable compressed air piping, ensuring compliance with these standards is essential for long-term efficiency and durability.

ReplyDeleteThe UV Light Accelerated Weathering Test Chamber is a species of laboratory equipment of effective lab india to simulate environmental conditions and assess the durability of materials. It uses UV light to repeat the effect of sunlight, rain and dew and accelerates the aging process of products such as coatings, plastic and textiles.

ReplyDelete