Following principals should be followed while

designing the instrument sensing line supports.

Hanger, support and clamps design should include

provision for seismic, pipe whip and thermal expansion of process taps and

instrument sensing lines to which the hangers, supports or clamps may be

subjected during normal operation, seismic or other credible events.

Material for hanger, clamps, pads and spacers in

contact with sensing lines should be compatible to avoid corrosion.

From the consideration of seismic qualification the

following supporting criterion should be followed:

a)

Supports should be placed at a distance of about 150 mm from each end of tube

fittings as well as bends in the tubing layout.

b)

Instrument isolating valves or other instrumentation valves coming in the sensing

lines should be supported with suitable clamps.

c)

In the intermediate tubing runs supports should be located in such a way that

the maximum unsupported span is not more than 1m.

From the consideration of thermal loading, tube

fittings and bends coming in the sensing lines should not be supported. This

criterion will be applicable for sensing lines/tubing where temperature cycling

is expected.

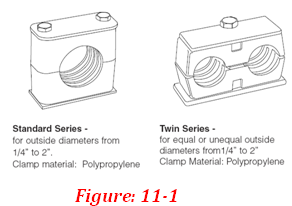

Tube Clamping

Once you’ve taken the time to make good bends and

installed them, it’s not enough to just let them lay suspended in mid-air. When

tubing is left unsupported, shock and vibration will cause the tubing to shake,

and in turn, cause the fitting to loosen and leak or even allow tube to fall

through fatigue.

Tube support and clamping is a necessary requirement

in the fluid power industry. Tubing can be clamped individually, in sets, and

can also be stacked. The most important part of any clamping system is having

enough clamps to attain the final result. That being, a well supported,

vibration and noise free system.

Also, most manufacturers specify SAE and JIC

approved components on their equipment. The best way to meet these specs

concerning clamps is to utilize a clamp that employs both an upper and lower

unit made of metal and a rubber split bushing which surrounds the tube or pipe

and fits on the inside of the clamping units.

Parker Hannifin offers a tube clamp support system

by the name of “ParKlamp”. ParKlamp can clamp and support tube fro m 1/4” to 2”

and pipe or hose fro m 1/4” to 1-1 /2”. It comes standard in steel and uses a

rubber grommet around the tube for vibration dampening.

Alongside Table-11-1 is showing maximum permissible

spacing between clamps. It is recommended to clamp as close to each bend of the

tube as possible; and one must clamp each side. This eliminates thrust in all

directions. The tube should be clamped at 1 m distance preferably. (See class-1

Tubing design)

Excellent article. Very interesting to read. I really love to read such a nice article. Thanks! keep rocking.

ReplyDeleteRobinets de Lavabo

we are trukky logistics an online truck transporter.We provide all kind of trucks at very affordable cost.

ReplyDeleteYou can check price online before booking it

Hyderabad to Delhi transporter services

Hyderabad to Ahmedabad transporter services

Hyderabad to Mumbai transporter services

Transporters in Delhi

See more about tube and clamp scaffolding for sale

ReplyDeleteGood and useful information. Thanks for sharing the blog. Sick sensor

ReplyDeleteHey guys, If you're looking for the trusted Turbine manufacturers company in India, feel free to check out Nconturbines.com who is doing best at their field. Don't miss it!

ReplyDeleteThank you for sharing this type of article. This was very knowledge full article for me. You keep sharing such an article. We get excellent knowledge by reading your article, thank you very much once again.

ReplyDeletePackers and movers in Sector 70 Gurgaon

Packers and movers in Sector 78 Gurgaon

Packers and movers in Sector 82 Gurgaon

Packers and movers in Sector 83 Gurgaon

Packers and movers in Sector 102 Gurgaon

Packers and movers in Sector 104 Gurgaon

Packers and movers in Sector 106 Gurgaon

Packers and movers in Civil Lines Gurgaon

Packers And Movers App

Valuable information,Thanks lot for sharing them with us.

ReplyDeleteGreat information on blog. keep posting.

ReplyDeletewe sell cutting machine in Mohali.

This comment has been removed by the author.

ReplyDeleteWell done! Your comprehensive observations and actionable recommendations are highly commendable. Find durable adjustable walkways at Sun Corporation, a trusted supplier of high-quality walkway planks and jalis. Designed for diverse terrains, our walkways ensure safety and stability. Explore our range for unbeatable value and expert support tailored to your project needs.

ReplyDelete