Different types of screw threads have evolved for

fastening, and hydraulic systems. Of special concern are plastic-to-metal,

taper/parallel threaded joints in hydraulic circuits. A discussion and

recommendations are provided to create an awareness of different types of threads

and how they are used.

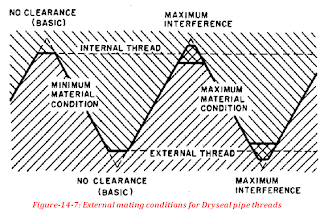

The minimum material condition as shown at the left is established by having the mating crests and roots of equal truncation so as to assure metal to metal contact at these points coincident with flank contact. The condition is established at the sharpest root and the flattest crest and gives no clearance. Tolerances at the crests and the roots are established in the direction of interference only, therefore the maximum material condition shown at the right is established by having the extreme combination of sharpest crests and flattest roots, which provide the maximum interference.

In the nineteenth century, many different types of

screw threads were required for hydraulic and pneumatic circuits as well as

fastening components. As a result, manufacturers started to devise their own

fastening systems. This resulted in compatibility problems. The English

mechanical engineer and inventor, Sir Joseph Whitworth devised a uniform

threading system in 1841 to address the incompatibility problem. The Whitworth

thread form is based on a 55 degree thread angle with rounded roots and crests.

In America, William Sellers set the standard for

nuts, bolts, and screws which became the National Pipe Tapered (NPT) Thread in

1864. His 60 degree thread angle, in common use by early American clockmakers,

enabled the American Industrial Revolution. These thread forms later became the

American National Standard.

The Whitworth thread form was selected as a

connecting thread for pipes, which was made self sealing by cutting at least

one of the threads on a taper. This became known as the British Standard Pipe

thread (BSP Taper or BSP Parallel thread). The Whitworth thread is now used

internationally as a standard thread for jointing low carbon steel pipes.

The best known and most widely used connection

where the pipe thread provides both the mechanical joint and the hydraulic seal

is the American National Pipe Tapered Thread, or NPT Thread. NPT has a tapered

male and female thread which seals with Teflon tape or jointing compound.

Pipe threads used in hydraulic circuits can be

divided into two types:

I. Jointing threads – are pipe threads for joints

made pressure tight by sealing on the threads and are taper external and

parallel or taper internal threads. The sealing effect is improved by using a

jointing compound.

II. Fastening threads – are pipe threads where

pressure tight joints are not made on the threads. Both threads are parallel

and sealing is affected by compression of a soft material onto the external

thread, or a flat gasket.

Pipe thread sizes are based on an inside diameter

(ID) or flow size. For example, “1/2 –14 NPT” identifies a pipe thread with a

nominal inside diameter of 1/2 inch and 14 threads to the inch, made according

to the NPT standard. If “LH” is added, the pipe has a left hand thread. The

most common global pipe thread forms are:

NPT - American Standard Pipe Taper Thread

NPSC - American Standard Straight Coupling Pipe

Thread

NPTR - American Standard Taper Railing Pipe Thread

NPSM - American Standard Straight Mechanical Pipe

Thread

NPSL - American Standard Straight Locknut Pipe Thread

NPTF - American Standard Pipe Thread Tapered

(Dryseal)

BSPP - British Standard Pipe Thread Parallel

BSPT - British Standard Pipe Thread Tapered

Plastic injection molded thread forms are

manufactured to ANSI B2.1 and SAE J476 standards. The word “tapered” in several

of the above names points to the big difference between many pipe threads and

those on bolts and screws. Many pipe threads must make not only a mechanical

joint but also a leak proof hydraulic seal. This is accomplished by the tapered

thread form of the male matching the thread form of the female tapered thread

and the use of pipe sealant to fill any voids between the two threads which

could cause a spiral leak. The bottoms of the threads aren't on a cylinder, but

a cone; they taper. The taper is 1⁄16 inch in an inch, which is the same as 3/4

inch in a foot.

Because of the taper, a pipe thread can only screw

into a fitting a certain distance before it jams. The standard specifies this

distance as the length of hand tight engagement, the distance the pipe thread

can be screwed in by hand. It also specifies another distance – the effective

thread, this is the length of the thread which makes the seal on a conventional

machined pipe thread. For workers, instead of these distances, it is more

convenient to know how many turns to make by hand and how many with a wrench. A

simple rule of thumb for installing tapered pipe threads, both metal and plastic,

is finger tight plus one to two turns with a wrench. Torque installation values

can be determined as per application, but due to the variations involved in

pipe joints such as dissimilar materials of male and female threads, type of

sealants used, and internal variations

in product wall thickness, a standard torque specification cannot be generically

applied.

This table shows the distances and number of turns

called for in the standard. A tolerance of plus or minus one turn is allowed,

and in pract ice threads are often routinely cut shorter than the standard

specifies. All dimensions are in inches.

Table-XVI-American Standard Taper Pipe External

Thread

Despite the standards created to maintain uniform

fittings, tapered pipe threads are inexact and during the course of use and

repair the threads can become damaged and susceptible to leakage. The area

where the crest and the root of the thread meet can form a spiral leak path no

amount of tightening will eliminate.

A pressure tight joint is achieved by the

compression in the threads resulting from tightening. This compression and

sealing occurs in the first few turns of the internal thread. As wrenching takes

place, material from both the male and female threads deform into each other.

This ensures full thread contact which minimizes spiral leakages. Variations

between injection molded plastic and machined metal thread forms can occur due

to different manufacturing processes.

Pipe threads were originally designed as machined

thread forms. With the use of thermoplastics and plastic injection molding in

the manufacture of plastic pipe thread forms, mold shrinkage and plastic sink

make it difficult to insure leak free joints. For this reason, the use of a

Teflon based sealant is recommended on all plastic pipe threads. The most

common form of sealant is Teflon tape wrapped 2 to 3 turns around the male

thread before assembly. Liquid Teflon based sealants are also used successfully

to ensure a pressure tight seal. It is always important to use care when applying

sealants to avoid introducing the sealant material into the system flow path.

The following sections show examples of how

different threads are used and issues that can arise in attempting to create a

leak free connection.

When a BSP tapered male thread is tightened into a

straight female thread (BSPP) the seal can only be made at the base of the

female port with 1 or 2 threads. See figure-14-1. Sealing is compromised by the

lack of thread form control in BSP specifications. Variation in crests and

roots may cause a mismatch in the thread and create a spiral leak. Thread

sealant is required to seal this combination.

Using both tapered male and female BSPT threads

would offer a better chance of sealing since you are now matching the taper of

the male and female thread. See figure-14-2. This offers more threads a chance

of sealing against spiral leakage. Crest and root control is still missing, but

with thread sealant, a pressure tight joint would be easier to accomplish.

A number of variations of the NPT thread have been

introduced to overcome the problem of spiral leakage and are known as Dryseal

threads (See SAE standard J476). The best known is the NPTF (F for Fuel). With

this thread design, there are controls on the crests and roots of both the male

and the female threads to ensure the crest crushes or displaces material into

the root of the mating thread. The interference fit between the crest of one

thread and the root of the other along with the thread flanks matching, seals against

spiral leakage. Figure 14-3 shows an NPTF male tightened into an NPTF female hand tight. You can see the crest of both the male

and female thread flanks meet.

Although these threads are considered Dryseal, a

Teflon tape or liquid is still recommended to aid in the assembly process.

The Teflon works as a lubricant to avoid galling of

the material when tightening the two threads together and also fills any voids

that may cause leakage.

However, in Nuclear power plants Teflon is not used

since its properties deteriorate very fast under radiation conditions.

A variation of the Dryseal thread is the NPSF

(National Pipe Straight Fuel). It is used for internal threads and a NPTF

external thread can be screwed into it to provide a satisfactory mechanical

connection and a hydraulic seal. The combination of a parallel and tapered is

not regarded as ideal but is widely used. High quality plastic quick disconnect

couplings typically use NPT threads.

thread is commonly used for low pressure plumbing, but

is not recommended for medium and high pressure hydraulic systems. This form

uses the Whitworth thread with an angle of 55°and a 1 in 16 taper. It is not

interchangeable with the American NPT thread, though at the 1/2" and

3/4" size, they both have 14 threads per inch.

Problems arise when threading a NPT male thread form

into a BSP female straight thread form. The

1/16”, 1/8”, 1/4”, and 3/8” sizes have a dissimilar

pitch, which causes a misalignment of the threads. The flank angles of the

threads are also different between NPT and BSP. NPT has a 60° thread where the

BSP has a 55° thread.

Figure 14-5 shows a male NPT tightened into a BSPP.

Because of the smaller size of the BSPP and the pitch difference, the NPT

tightens with only a few turns.

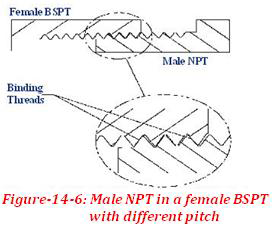

Figure 14-6 shows an NPT tightened into a BSPT. The

NPT thread to engage further, but pitch difference eventually causes a binding

of the threads. Pitch and thread angle differences will allow spiral leakage.

The 1/2” and 3/4” sizes in the NPT and BSP are all

14 threads per inch, and the NPT will engage the BSP fairly well.

Although these threads are the same pitch and

engage well there are still issues with the tread form. The thread angles and

the crest and root tolerances being different will allow spiral leakage as

shown in figure 14-6. These threads might be used effectively together if an

appropriate thread sealant is incorporated.

Many issues arise when plastic quick disconnect

couplings, with their corresponding injection plumbed into metal piped

hydraulic systems. Leaks and plastic thread form failures may occur if care is

not taken. When investigating a metal to plastic pipe joint failure, two

factors viz. chemical attack and over tightening, need to be considered. Chemical

attack can occur when improper thread sealants are used. Thread sealing is an attempt

to block the spiral leak path which occurs when the crests and roots of the

thread forms do not match. Anaerobic thread sealants should be avoided when

sealing plastic thread forms. These sealants contain chemicals which may attack

plastics. Use of a Teflon-based pipe thread sealant is a better choice for

plastic threads.

Over tightening of any plastic pipe thread will

have adverse affects on the function of the joint. The major difference between

plastics and metals is the behavior of polymers. Injection-molded plastic parts

continue to deform if they are held under a constant load e.g. creep. Creep is

the continued extension or deformation of a plastic part under continuous load.

Typically the plastic material in an injection-molded plastic pipe thread form

will creep from being over tightened into a female tapered port. The

deformation of the part’s internal features can lead to part failure.

Dryseal pipe threads are based on the USA

(American) pipe thread; however, they differ from the USA (American) pipe

thread in that they are designed to seal pressure tight joints without the

necessity of using sealing compounds. To accomplish this some modification of

thread form and greater accuracy in

manufacture is required.

The roots of both external and internal threads are

truncated slightly more than the crest, i.e. roots have wider flats than the

crests, so that metal to metal contact occurs as the crests and the roots

coincident with or prior to flank contact, see figure-14-7. Thus as the threads

are assembled wrenching, the roots of the threads crush the sharper +crests of

the mating threads .This sealing action at both the major and

minor diameters tends to prevent spiral leakage and

pressure tight without the necessity of using sealing compounds, provided that

the mating threads are in accordance with standard specification and tolerance

and are damaged by galling in the assembly. The control of crest and root

truncation is simplified by the use of properly designed threading tools. Also

it is desirable that both for the length. However, where not functionally

objectionable, the use of a compatible lubricant or sealant may be used to

minimize the possibility of galling. This is desirable in assembling dryseal

pipe threads in refrigeration and other systems to affect a pressure tight

seal.

In order to obtain a pressure tight seal using

dryseal pipe threads without a sealer, it is necessary to hold crest and

truncation of both internal and external threads within the limits specified.

Unless this is done by use of threading tools with the crest and root

truncation controlled so assure reproduction on the product of threads, it is

necessary to use a system of measuring or a system of gauging and measuring to

determine conformance.

There are two classes of Dryseal pipe threads viz.

Class-I and Class-II Dryseal pipe threads. The classes differ only in

inspection requirements. For class-I threads, inspection of roots and crest is

not required while for class-Ii threads these inspections are required.

External Dryseal threads are tapered only while

internal Dryseal threads may be either straight or tapered. Also, the thread

lengths may be either standard or short depending on the requirement of the

application. Short threads are obtained by shortening the length of the

standard thread by one pitch.

The minimum material condition as shown at the left is established by having the mating crests and roots of equal truncation so as to assure metal to metal contact at these points coincident with flank contact. The condition is established at the sharpest root and the flattest crest and gives no clearance. Tolerances at the crests and the roots are established in the direction of interference only, therefore the maximum material condition shown at the right is established by having the extreme combination of sharpest crests and flattest roots, which provide the maximum interference.

When threaded joints are made wrench tight, it is

intended that the flanks and crests and roots shall be in contact.

It's very informative blog post. Can anyone tell me if there is any good book on hydraulic engineering? I want to buy one for myself.

ReplyDeleteHydraulic Seal Kits

Thanks

Henry Jordan

The comprehensive detail about pipe fittings is a valuable for every one specially for a professional and students. Nice tips and guidelines. I am impressed by Swagelok pipe fittings.

ReplyDeleteIndeed Swagelok pipe fitting is impressive.

ReplyDeleteswagelok ss-4p4t is a valuable addition by the supplier.

http://www.industrialzone.com/67471-swagelok-ss-4p4t.html

Widespread Industrial supplies has products like Copper Pipe Fittings for many diverse industries, including - Oil Refineries, Automotive Repair and Maintenance, Machine Shop, Metro Maintenance Shops, Manufacturing Plants, MRO Facilities, County Correctional Facilities, City and County Maintenance Yards includes all bellow hardware.

ReplyDeleteYou can download the pdf version of this document on Instrumentation and Control

ReplyDeleteThank you!

nice post on threaded fittings can u write more on shims

ReplyDeleteThis is my first time i visit here. I found so many interesting stuff in your blog especially its discussion. From the tons of comments on your articles, I guess I am not the only one having all the enjoyment here! keep up the good work

ReplyDeleteRobinets de Lavabo

Hey what a brilliant post I have come across and believe me I have been searching out for this similar kind of post for past a week and hardly came across this. Thank you very much and will look for more postings from you.

ReplyDeletefittings manufacturer

Thanks for such a continuous great postings.

ReplyDeletePiping Insulation

Cathodic Protection System

Such a nice post! I was looking for more details about Hydraulic Hose Fittings area. Then I reached here and got helpful information.

ReplyDeleteNingbo Pneumatic Technical Expert Co Ltd is abode to one of the best check valves Zhejiang and other products at great costs. Their entire client’s projects are handled personally by their professionals for outstanding quality in work.

ReplyDeleteBest Check Valves Zhejiang

Plastic Tubing Connectors

Thanks for Sharing this awesome blog. You can also visit: Bolt Manufacturer in India

ReplyDeleteExcellent information, thanks for providing the most exclusive deals on marketing practice which is really a good way to sale online products of pipes. Get more details

ReplyDeleteThanks for sharing usefull information with us. I am looking forward to more from you. If want to know about Plastic Molding machine so you can visit their.

ReplyDeleteFlexFit Hose LLC provides valves, fittings, stainless tubing, stainless steel adapters, stainless sanitary clamps, gaskets, and accessories.

ReplyDeleteNice blog! This is useful for those who is looking for the Pisco Air Fittings. Keep Sharing such information blog.

ReplyDeleteGreat information on blog. keep posting.

ReplyDeletewe sell single phase welding machine

.

Thank you for taking the time to publish this information very useful article. Thank you for providing this information about pisco air fittings.

ReplyDeleteBefore departing from your site, I wanted to convey my sincere enjoyment of the high-caliber information you offer about Plastic Pipe your readers. I'll be a regular visitor to stay updated with your new content.

ReplyDelete